3D modelling as easy as playing with dolls

This simple device will change the world! It’s an essential step to breaking down the barrier to robotics, 3D printing, and 3D media.

This action figure allows anyone with a computer and free software to create 3D animations. Move the arm of the doll and the arm on the screen moves the same way. This is the most intuitive way to work.

Powerful low cost computers and free software have enabled anyone to produce media as good or better than professionals. Even though the basic tool are available to anyone, 3D modeling has remained too difficult for most people because it required specialized skills to draw the models. A literal hand-on user interface bring 3D modeling to anyone.

The difficulty of 3D modeling isn’t just a problem for media it limits the progress of 3D fabricating like 3D printing and CNC. If you can literally move objects you can focus on the results instead of how to communicate with the computer.

Using a computer allows you to do many things you can’t just by hand. You can work on objects much smaller or larger than you could in real life. You can record the movements then edit those movements later or make small adjustments . After recording the movements you can play them back or direct robot / printer / CNC machine to perform the task. And the machine can do it much faster or slower than you can manually do. This opens up vast possibilities.

Simple intuitive user interfaces combined with exiting robotics will change the world.

Abundance Report: Solar 3D Printer Builds from Sand

Markus Kayser – Solar Sinter Project from Markus Kayser on Vimeo.

Markus Kayser has built a 3D printer that uses sun light to turn sand into 3D glass objects. Free energy making things from the free materials.

He calls the device a Solar Sinter. The process works by spreading thin layers of sand then focusing a beam of light with a magnifying lens on a point to melt the sand turning it into glass. The object is built up a layer at a time. The movement and focusing of the beam is powered with photovoltaic but the high energy melting is done with a magnifying lens. This allows the device to be very low cost and potentially long lasting

A rover equipped with a solar sinter could be placed in deserts on earth or another planet and let run making useful objects. Even though this device makes crude items similar 3D printing technology has been used to make high precision objects of many materials.

In addition to a 3D printer, which is an additive technique, he has made a solar cutter which is a subtractive technique.

Markus Kayser – Sun Cutter Project from Markus Kayser on Vimeo.

Solar Cutter

3D Printer / CNC head positioning ideas

Ideas to make high precision low cost head positioning systems for 3D printer / fabricators / CNC machines. Precision stepper motors are expensive. What if you could use cheap analog motor? They could be very fast and cheap.

Electrical Resistance

Run a length of wire along each axis of the printer / fabricator / CNC and measure the resistance at the head position. Using a table of actual resistance measurements on the device could increase accuracy and even heat differences could be taken into account. This could be extremely accurate and low cost.

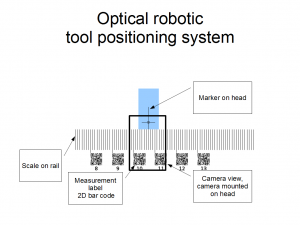

Optical

Optical is another approach, this is how mechanical mice and mane printers function. Using a digital camera with distance measurements on a scale printed from a long format printer could make the device very fast and accurate. Using optics the accuracy could increased fine precision even with cheap webcam sensors.

RF Triangulation

Mounting an RF transmitter on the head and antennas at the corners of the tracks could allow triangulation of the head to extremely high precision even over very large distances. This is the same technique used by GPS and cell phone towers. The precisions scales with size and frequency transmitted.

Electrical Balancing

Using opposing electrical currents to create a balance for any location along the rail. With the correct calibration this can be very accurate plus provide very fast movement.

Predictive Innovation Training

Predictive Innovation Training Predictive Innovation: Core Skills Book

Predictive Innovation: Core Skills Book RoundSquareTriangle.com

RoundSquareTriangle.com