How SpaceX Could’ve Easily Avoided the Crash

The recent SpaceX failure could have been easily avoided by using a cheap simple device they could have figured out in a few minutes by using Predictive Innovation.

The recent SpaceX failure could have been easily avoided by using a cheap simple device they could have figured out in a few minutes by using Predictive Innovation.

The goal of landing the rocket vertically is both to reuse the rocket on Earth but also to develop the ability to land and return from the Moon, Mars, or asteroids to be mined. So they don’t want to only avoid damaging the rocket during landing, they want to build a rocket that is flexible enough to take off, land, and take off again on a wide range of surfaces. A lot can be learned from failures but there is no point destroying the rocket just to learn a little more.

What is the cheap simple solution for SpaceX?

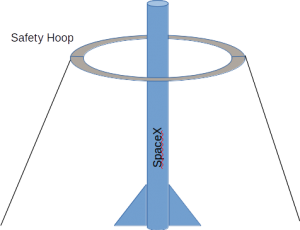

The solution is like a large basket ball hoop over the landing pad. The rocket would land the same way and in the same place but first go through the hoop. The hoop should be large enough to not interfere with positioning and landing but small enough and high enough to catch the rocket if it tipped over. This protects the rocket from smashing on the landing pad and exploding. It would also allow all the data to be collected to learn how to land without the hoop. At the point the rocket falls over the experiment failed so nothing new can be learned. No point in risking damage to the rocket after the lesson is learned.

There is even a similarly cheap & easy way to use this concept for landing on uncharted territory such as Mars. I know that Elon Musk likes using first principles to innovate. The first principles of information is the basis of Predictive Innovation. Elon, give me a call, I also have a patented way to make solar panels for $0.25 / kW and a way to turn eWaste in to precious metals and plant food using 1/10th the energy of other less environmentally friendly systems.

P.S. This offer isn’t exclusive to Elon, unless he calls me first 😉

P.P.S. I can also help your organization with your seemingly impossible problems with a 100% guarantee.

3D Printer / CNC head positioning ideas

Ideas to make high precision low cost head positioning systems for 3D printer / fabricators / CNC machines. Precision stepper motors are expensive. What if you could use cheap analog motor? They could be very fast and cheap.

Electrical Resistance

Run a length of wire along each axis of the printer / fabricator / CNC and measure the resistance at the head position. Using a table of actual resistance measurements on the device could increase accuracy and even heat differences could be taken into account. This could be extremely accurate and low cost.

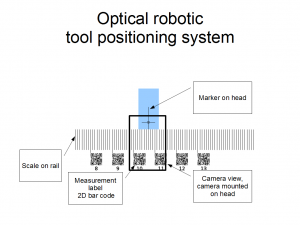

Optical

Optical is another approach, this is how mechanical mice and mane printers function. Using a digital camera with distance measurements on a scale printed from a long format printer could make the device very fast and accurate. Using optics the accuracy could increased fine precision even with cheap webcam sensors.

RF Triangulation

Mounting an RF transmitter on the head and antennas at the corners of the tracks could allow triangulation of the head to extremely high precision even over very large distances. This is the same technique used by GPS and cell phone towers. The precisions scales with size and frequency transmitted.

Electrical Balancing

Using opposing electrical currents to create a balance for any location along the rail. With the correct calibration this can be very accurate plus provide very fast movement.

Ham boning robot, Abundance Report

Meat cutting is a dangerous, physically stressful, and tedious job. Replacing human meat cutters with robots is all around better if the humans have an income.

The representative repeatedly says the robots can cut oddly shaped soft objects. He is making clear that cutting ham is not the only use. The robot can cut a wide variety of foods but also non-food. They’ve likely chosen ham boning as their first task because the size makes it easier than smaller or more delicate food like fish and improving ham processing is higher value than vegetables. Defining the goal properly and finding the best entry to the market is very important for innovation success.

The makers of the Hamdas robotic meat cutting machine, Mayekawa, also make many environmentally friendly energy saving innovations. They are looking at the full range of interconnected innovations. They are using what Predictive Innovation® calls a Future Map. Each of their innovations builds on part of the other thus making each one less expensive and less risky to develop and higher value.

Many of the comments to the video bring up the concern jobs being eliminated. How can human meat cutters have an income when the job of cutting meat is done by machines? The common answer of making or repairing robots is fatally flawed. Repairing robots will not require as many people as the jobs the robots replace. The best way for meat cutters to have an income when robots are doing the work is to own robots. This way the people are still meat cutters, they just aren’t doing the physical work.

Another alternative for displaced workers is to do something else that robots makes possible. This unfortunately will likely displace other workers. Automation replaces people in any task that is done more than once. The solution is to focus on things that can’t be replicated. Personal experiences are one thing that can’t be duplicated. Satisfying those desires will be large growth area over time. In the short term, anything that helps individuals and small groups own the machines that makes things will be a crucial part of making the transition from economics to abundance.

Predictive Innovation Training

Predictive Innovation Training Predictive Innovation: Core Skills Book

Predictive Innovation: Core Skills Book RoundSquareTriangle.com

RoundSquareTriangle.com