Compact Fluorescent Bulb Recycling

I volunteer at AllExperts.com. One of the questions I received makes an interesting example. This is not a complete OutCompete analysis, just a very fast list of suggestions.

Question:

Retailers have implemented programs for the safe disposal of compact fluorescent bulbs. However the current process requires the involvement of an store employee. I would like to design a system which does not require the involvement of an employee. My assumption right now is:

- The system is for compact fluorescent lamps, medium base type bulbs.

- The system that can accommodate at least 200 CFL’s before needing to be emptied.

- The system would reward the customer for their effort.

I would like your advice on this system, on how to design it and what reward I should consider. Could you also suggest a website which will provide me information for my design system.

Thank you.

Answer

The OutCompete Predictive Innovation Method works best if we can work with a subject matter expert to verify the technical aspects of ideas.

The Predictive Innovation Method follows these steps:

- Create “Desire Statement”

- Convert Desire Statement into on Outcome diagram

- Expand each of the Outcomes into their 7 elements types

- Using the Alternatives Grid to multiply those 7 types by the 15 alternatives to reveal a minimum of 105 potential innovations.

Since I am not exactly a subject matter expert on recycling mercury I’ll focus on one aspect that I was able to find information about.

The main problem with the mercury in a CFL is breathing in vapor or dust from broken bulbs. As long as they are not broken there isn’t any problem.

http://www.energystar.gov/ia/partners/promotions/change_light/downloads/Fact_Sheet_Mercury.pdf

Video of mercury evaporating

http://www.michigan.gov/mdch/0,1607,7-132-2945_5105_47868-181553–,00.html

So the primary goal of collecting CFLs is making the mercury vapor safe to people. Here are a few approaches.

- Prevent the vapor from being released.

- Don’t break the bulbs

- Contain the vapor if broken

- Keep vapor away from people

- Make the vapor safe

Two ideas come to mind. Have a single container to hold many bulbs air tight

- pull air in and vent safely outside

- pull air in through and filter air inside container

- submerge the bulbs in a liquid that mercury vapor is heavier than so it collects on the bottom and is safely contained

- Contain each bulb, put each bulb in an airtight bag so it doesn’t matter if the bulb breaks. This material would have to be easy to recycle with the rest of the bulb

This company has a filter for the vapor, but you could probably be OK just venting it outside.

http://www.ohiolumex.com/product/vapor_filter.shtml

The basic problem with getting people to recycle is making the effort more valuable than throwing the item away in the regular garbage. You can do this by appealing to their emotions or by actually making it easier. You will likely need to do both.

Since CFL are suppose to last a long time the purchase is long removed from the disposal. However people usually replace a bulb the instant one stops working. If they have bulbs on hand it is probably in some type of safe container to prevent it from being broken. If this could serve as a safe recycling container it would be effective.

Alternatively the person will need to go to the store to get a new bulb. This is when to prompt for recycling the old bulb.

- give the consumers something for bringing bulbs in, such as a discount on new bulbs

- eliminate another problem by bringing the bulbs in

- provide a container to store the bulbs until returned

- have a deposit similar to the $0.10 bottle deposit in Michigan (this practically eliminated that type of pollution)

Summary

With this information it would be easy to find and affordable solution to the problem. You’ll also notice that there are several possibilities for future innovation or product improvements. For instance combining the ideas :

- provide a container to store the bulbs until returned

- Contain each bulb, put each bulb in an airtight bag so it doesn’t matter if the bulb breaks. This material would have to be easy to recycle with the rest of the bulb

These two outcomes can be achieved at the same time.

First Step for Dental Innovation “No Cavity”

I had a cavity and the American dentist gave me only one option and I didn’t like it. I wanted better options. So I started innovating to satisfy my desire. Before you think that I started inventing something let me clarify innovation. Innovation is satisfying a demand. If you can find something that already exists and use it to satisfy the demand you innovated. So I began searching. The innovation I wanted was No cavity.

Since I wasn’t an expert on dentistry I did a little research to understand at a high level how dental caries (cavities) function.

Acid from bacteria eat left over food and cause decay in teeth. Your mouth has a natural defense for the acid. Your saliva is alkaline, it neutralizes acid. Unfortunately bacteria can stick to teeth blocking saliva from neutralizing the acid.

Saliva has another positive feature. If the infection that causes decay is caught early enough teeth re-mineralize all on their own using material in your saliva.

If too much damage is done there is a hole that could collect food and bacteria. Once that hole gets through the hard enamel, a cavity can quickly grow in the softer dentin. It’s still possible for a tooth to heal at this point but often some type of repair is needed. But most important is stopping the infection and decay.

Many cavities form in areas of teeth that catch food and are hard to clean. The tendency for bacteria to stick to teeth makes this even worse.

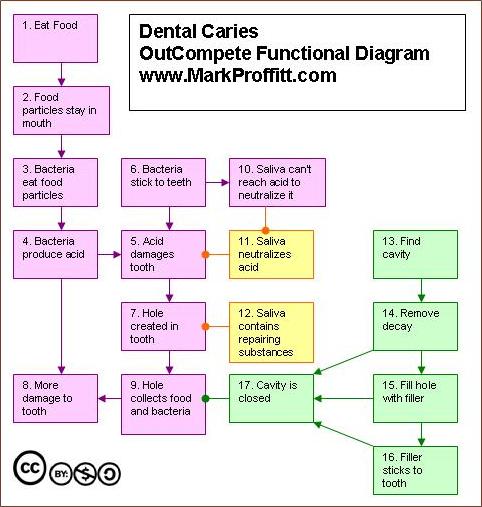

Functional Diagram

Taking all the information I gathered I created a Functional Diagram. The red boxes describe how cavities work. The green boxes describe the process of filling a cavity. And the yellow boxes show the natural process of saliva re-minerizing teeth.

The Functional Diagram give you a high level starting point to start looking for innovation alternatives.

Predictive Innovation Training

Predictive Innovation Training Predictive Innovation: Core Skills Book

Predictive Innovation: Core Skills Book RoundSquareTriangle.com

RoundSquareTriangle.com