First Step for Dental Innovation “No Cavity”

I had a cavity and the American dentist gave me only one option and I didn’t like it. I wanted better options. So I started innovating to satisfy my desire. Before you think that I started inventing something let me clarify innovation. Innovation is satisfying a demand. If you can find something that already exists and use it to satisfy the demand you innovated. So I began searching. The innovation I wanted was No cavity.

Since I wasn’t an expert on dentistry I did a little research to understand at a high level how dental caries (cavities) function.

Acid from bacteria eat left over food and cause decay in teeth. Your mouth has a natural defense for the acid. Your saliva is alkaline, it neutralizes acid. Unfortunately bacteria can stick to teeth blocking saliva from neutralizing the acid.

Saliva has another positive feature. If the infection that causes decay is caught early enough teeth re-mineralize all on their own using material in your saliva.

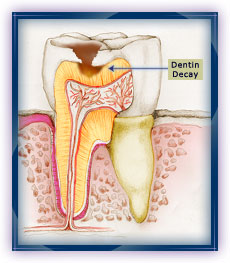

If too much damage is done there is a hole that could collect food and bacteria. Once that hole gets through the hard enamel, a cavity can quickly grow in the softer dentin. It’s still possible for a tooth to heal at this point but often some type of repair is needed. But most important is stopping the infection and decay.

Many cavities form in areas of teeth that catch food and are hard to clean. The tendency for bacteria to stick to teeth makes this even worse.

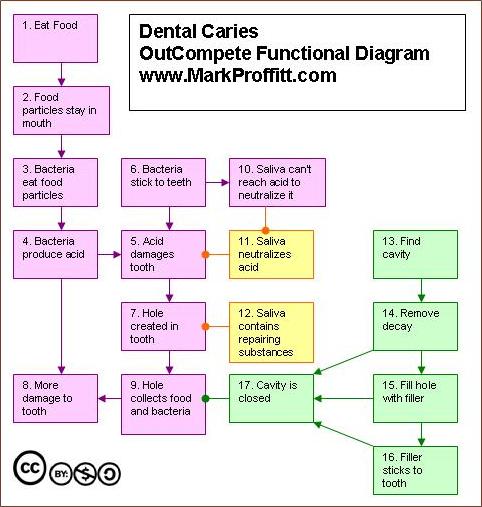

Functional Diagram

Taking all the information I gathered I created a Functional Diagram. The red boxes describe how cavities work. The green boxes describe the process of filling a cavity. And the yellow boxes show the natural process of saliva re-minerizing teeth.

The Functional Diagram give you a high level starting point to start looking for innovation alternatives.

3D Printer Brings Vision to the Poor

The same week that I found all the articles on 3D printers I found an amazing example that could dramatically improve life for billions of people in developing countries who cannot access, nor afford, prescription glasses.

Last weekend I went to get a new optical prescription so I could buy new contacts. The technician used fully automatic devices to check me for glaucoma and calculated my prescription. I had experienced the glaucoma device but the prescription device was new to me. I instantly knew how it worked just from seeing it. The machine reflects a pattern off your eye then adjusts lenses in the device until the reflected pattern matches the original. Incredibly, quick easy and cheap!

My mind raced through all the potential innovations stemming from this device. I came up with a long list which I’ll get to in a moment. What I am more excited about is an extremely innovative application of this same technique. In 2002 a student at MIT used a similar technique as part of a system to make glasses for the poor. This was exactly what I had thought of. This innovation went from an idea in 2002 to commercial usable device in 2006. That is amazing.

One of the reasons the idea was developed in such a short time was the use of a 3D printer to create a prototype. But probably even more important was it solved a previously impossible problem and opened up a gigantic market. There are 1 billion people who need inexpensive glasses.

There are two obstacles to providing eye glasses to people in developing countries. Read more

Predictive Innovation Training

Predictive Innovation Training Predictive Innovation: Core Skills Book

Predictive Innovation: Core Skills Book RoundSquareTriangle.com

RoundSquareTriangle.com